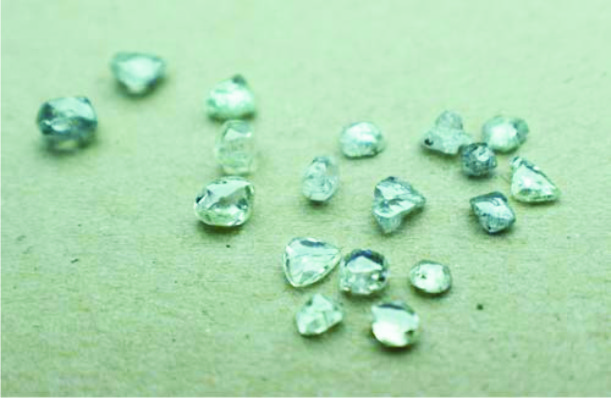

Tsodilo Resources Limited in an update on its diamondiferous BK16 kimberlite, which is known to contain rare and valuable Type IIa diamonds, said that the first two parcels of diamonds (101 stones – 18.571 carats and 130 stones – 17.791 carats) were delivered to Lucara Diamond Corp. for cleaning at itsacid cleaning laboratory located at the Diamond Technology Park (DTP) in Gaborone, Botswana. The two parcels consist of diamonds recovered up to May 4, 2018.

Once the process is completed, the diamonds will be stored in the secured facilities of I Hennig & Co. at the DTP.

The Company highlightedthe excellent position of the BK16 kimberlite project which is located within the Orapa Kimberlite Field (OKF) in Botswana. “The diamond mines in Botswana have produced an average of 27 million carats annually in the last 10 years and Botswana is the world’s largest producer of diamonds by value,” Tsodilo noted. “In 2017, the OKF area produced 11.07 million carats. Of the 83 known kimberlite bodies, eleven have been or are currently being mined.”

Most of these are being mined by well-known companies like Debswana, Lucara Diamond Corporation, and Firestone Diamonds; all of which have reported notable success with their fields.

“The Karowe mine has produced such notable diamonds as the 1,109 carat `Lesedi La Rona` and the 813 carat `Constellation’,” Tsodilo underlined.

The Company said Ray Ferraris of QTS-Kristal Dinamika – South Africa, has been retained “to initiate a size frequency distribution (SFD) study as well as a Diamond Reconstruction and Breakage study (DRB) study”, once the stones have been acidised.

The SFD study will help the Company project the diamond size frequency in a diamond deposit, thus contributing significantly to estimating revenue.

The DRB study on the other hand helps to establish “a first-order profile for the extent and nature of diamond breakage related to natural or imposed industrial causes”.

The Company will be able to provide final diamond counts and compile initial weights, once all samples have been processed, sorted, and a thorough tailings re-treatment audit has been completed.

“Detailed breakage descriptions and resorption characteristics; definitions of habit, color, size distributions; sample grade calculations; and commercial characteristics will be finalized once all the diamonds have been cleaned by acid treatment,” Tsodilo concluded.

News Source : gjepc.org

Disclaimer: This information has been collected through secondary research and TJM Media Pvt Ltd. is not responsible for any errors in the same.